Durable, dependable and decidedly cost-efficient: The Ultra Air Barrier Wall System

What you’re used to just got better

By Doug Todd

With the Ultra Air Barrier Wall System from Dow Building Solutions, masonry contractors now have an economical system that is easy to install and keeps more of the contract under the mason’s control. Combining a continuous, high R-value rigid insulation AND an air/vapor and water barrier, Ultra Air Barrier Wall System can give contractors a competitive advantage for brick and block or steel stud cavity walls without sacrificing quality.

We’re building on a great idea. The Ultra Air Barrier Wall System now works for both brick/block and steel stud applications.

What you’re used to just got better. Trusted products. Trusted name.

Rethinking Masonry Cavity Wall Design For Insulated Block and Steel Stud Walls

Building on field input and demand, the Ultra Air Barrier Wall System can be used on steel stud backup walls, in addition to brick/block cavity walls. Regardless of the backup supporting wall, the Ultra Air Barrier Wall System offers a layer of continuous insulation and a properly detailed air/vapor and water barrier together in one easy-to-install package. The result is a cost-efficient yet effective system that offers essential continuous insulation and an air/vapor and water barrier in cavity wall systems.In the past, contractors often installed a separate air/water barrier then covered it with insulation. This two-step process was not only labor-intensive and expensive, but often created issues with maintaining continuity during installation and commissioning. With fewer steps than standard construction methods, the Ultra Air Barrier Wall System can save contractor’s time and money.

Contractors have used these tried and true Dow Building Solutions products separately over the years but the Ultra Air Barrier Wall System puts them together in a new and innovative way.

The Ultra Air Barrier Wall System at a glance

- One solution for continuous insulation and an air/vapor and water barrier for both brick/block or steel stud backup walls

- High R-value: R-5.62 per inch

- Meets ASTM E2357 wall assembly test and ASHRAE 90.1 for continuous insulation and air barriers

- Passed ASTM E331 water leakage test

- Approved air barrier assembly by the Air Barrier Association of America (ABAA)

- Meets NFPA 285 requirements3

- Easy-to-install: no extra protective measures, no overspray to clean up

- 15 ¾” wide insulation fits between traditional pre-installed/integrated anchors or the new 4’ x 8’ insulation board with a shiplap edge can be used with other post-installed anchors

- Easy-to-maintain cavity wall air gap

- Sealing joints with either WEATHERMATE™ Flashing Tape or GREAT STUFF PRO™ Gaps & Cracks Insulating Foam Sealant1 eliminates the need for an additional weather-resistant barrier

- Compatible with a range of Dow complementary products

- Industry-recognized products with proven performance and installer confidence

- Because the system can be installed over a wide range of environmental conditions, scheduling is simplified over block wall installations

| Ambient temperature | 25 °F or higher for best results. |

| Substrate temperature | 25 °F or higher for best results. |

| Moisture % of wall | Do not install when raining. |

Two Ultra Air Barrier Wall System Solutions using Industry-Recognized Dow Products

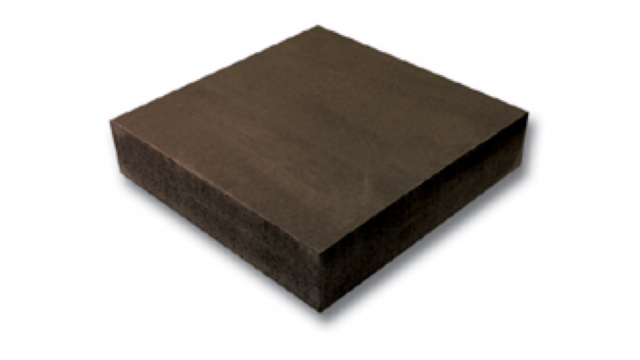

Now contractors have an Ultra Wall Barrier System solution depending on whether the brick anchor is pre-installed or integrated (uses 15 ¾” wide insulation) or post-installed (uses 4’ x 8’ insulation.)15 ¾” STYROFOAM™ Brand CAVITYMATE™ Ultra Solution

For brick and block walls with pre-installed or integrated brick anchors, the system uses specially sized 15 ¾” wide x 8’ long, square edge STYROFOAM™ Brand CAVITYMATE™ Ultra Insulation boards placed between the anchors. Air/vapor and water barrier properties are achieved by sealing the insulation board joints with single-component GREAT STUFF PRO™ Gaps and Crack Insulating Foam Sealant.1 (See Figure 1)4’ x 8’ STYROFOAM ™ Brand Ultra SL Solution

For continuous brick and block backup walls or steel stud back up wall, larger 4’ x 8’ sheets of STYROFOAM™ Brand Ultra SL Insulation with a shiplap finish on the long side are mechanically fastened and then anchors post-installed. In this solution, air/vapor and water barrier properties are achieved by sealing the insulation board joints with WEATHERMATE™ Flashing Tape. GREAT STUFF PRO™ Gaps and Crack Insulating Foam Sealant.1 is used to seal the bottom row of the STYROFOAM™ Brand Ultra SL Insulation board along the base. (See Figure 2 (block backup wall) and Figure 3 (steel stud backup wall)

Ultra Air Barrier Wall Selection Guide

| Cavity Wall Design | Ultra Air Barrier Wall System |

| Wall anchors pre-installed on brick and block cavity walls. See Figure 1. | 15 ¾" STYROFOAM™ Brand CAVITYMATE™ Ultra Solution Uses STYROFOAM™ Brand CAVITYMATE™ Ultra Insulation and GREAT STUFF PRO™ Gaps & Cracks Insulation Foam Sealant.1 |

| Wall anchors post-installed on brick and block cavity walls. See Figure 2. | 4' x 8' STYROFOAM ™ Brand Ultra SL Solution Uses STYROFOAM™ Brand Ultra SL Insulation, WEATHERMATE™ Flashing Tape and GREAT STUFF PRO™ Gaps & Cracks Insulating Foam Sealant.1 (Bottom row only) |

| Wall anchors post-installed on steel stud backup wall. See Figure 3. |

Why use the Ultra Air Barrier Wall System?

Model energy codes – ASHRAE 90.1 “Energy Standard for Buildings Except Low-Rise Residential Buildings” and “International Energy Conservation Code” (IECC) - recognize the need for both continuous insulation (ci) and air sealing. In fact, recent code changes now make both requirements mandatory in most climate zones. Many contractors are challenged to find approaches that not only meet these requirements, but can also be easily and economically delivered in the field. Fortunately there is the Ultra Air Barrier Wall System.Both rigid insulations used in the Ultra Air Barrier Wall System can completely block any air infiltration, meeting ASTM E2357 air barrier test requirement for a maximum air permeance no greater than 0.04 cfm/ft2. However the board joints must be sealed to achieve the specified air barrier properties.

When the joints of the insulation are sealed with either GREAT STUFF PRO™ Gaps and Crack Insulating Foam Sealant or WEATHERMATE™ Flashing Tape - depending on the Ultra Air Barrier System solution used - the resulting layer of insulation and sealant becomes an effective air barrier. This air barrier system has been tested and meets the requirements of ASTM E2357.

For added confidence, the Ultra Air Barrier Wall System has been approved by the Air Barrier Association of America (ABAA) as an air barrier material and assembly.

Support Tools

Here’s everything you need to start designing with Ultra Air Barrier Wall System today.- Installation Instructions

- Installation videos

- CAD details

- Answer Center

- Guide specifications

- Warranty

Save Time, Effort and the Expense of Both

The Ultra Air Barrier Wall System - leveraging the strengths of familiar products such as STYROFOAM™ Brand CAVITYMATE™ Ultra Insulation, STYROFOAM™ Brand Ultra SL Insulation, GREAT STUFF PRO™ Gaps and Crack Insulating Foam Sealant and WEATHERMATE™ Flashing Tape - offers an easy-to-install, cost-effective solution to meet code requirements for continuous insulation and air/vapor and water barriers in one simple solution.Durable, dependable and decidedly cost-efficient.

Learn more at www.ultrawallsystem.com or call us at 1-866-583-BLUE (2583).

Notice: No freedom from infringement of any patent owned by Dow or others is to be inferred. Because use conditions and applicable laws may differ from one location to another and may change with time, Customer is responsible for determining whether products and the information in this document are appropriate for Customer's use and for ensuring that Customer's workplace and disposal practices are in compliance with applicable laws and other government enactments. The product shown in this literature may not be available for sale and/or available in all geographies where Dow is represented. The claims made may not have been approved for use in all countries. Dow assumes no obligation or liability for the information in this document. References to “Dow” or the “Company” mean the Dow legal entity selling the products to Customer unless otherwise expressly noted. NO WARRANTIES ARE GIVEN; ALL IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE ARE EXPRESSLY EXCLUDED.

STYROFOAM™ Brand Extruded Polystyrene Foam Insulation

CAUTION: This product is combustible and shall only be used as specified by the local building code with respect to flame spread classification and to the use of a suitable thermal barrier.WARNING: Rigid foam insulation does not constitute a working walkable surface or qualify as a fall protection product.

Dow Polyurethane Foam Insulation and Sealants

CAUTION: When cured, these products are combustible and will burn if exposed to open flame or sparks from high-energy sources. Do not expose to temperatures above 240ºF (116ºC). For more information, consult MSDS, call Dow at 1-866-583-BLUE (2583) or contact your local building inspector. In an emergency, call 1-989-636-4400 in the U.S. or 1-519-339-3711 in Canada. When air sealing buildings, ensure that combustion appliances, such as furnaces, water heaters, wood burning stoves, gas stoves and gas dryers are properly vented to the outside., See website: http://www.epa.gov/iaq/homes/hip-ventilation.html.GREAT STUFF PRO™ Insulating Foam Sealants contain isocyanate and a flammable blowing agent. Read the label and MSDS carefully before use. Eliminate all sources of ignition before use. Wear long sleeves, gloves, and safety glasses or goggles. Provide adequate ventilation or wear proper respiratory protection. Contents under pressure.

GREAT STUFF PRO™ Gun Cleaner is flammable and contains acetone and propane. Read the label and MSDS carefully before use. Eliminate all sources of ignition before use. Wear gloves, and goggles or safety glasses. Provide adequate ventilation or wear proper respiratory protection. Contents under pressure.

Building and/or construction practices unrelated to building materials could greatly affect moisture and the potential for mold formation. No material supplier including Dow can give assurance that mold will not develop in any specific system.

1) Consult Material Safety Data Sheet and label carefully before use.

2) R means resistance to heat flow. The higher the R-value, the greater the insulating power. R-values are expressed in ft2• h•°F/Btu. R-value determined by ASTM C518.

3) Meets NFPA 285 per Section 2603.5.5 of the building code. For specific assemblies, see code report ESR 2142.

®™ Trademark of The Dow Chemical Company (“Dow”) or an affiliated company of Dow.

About the Author

Doug Todd is a Market Manager for Dow Building Solutions.