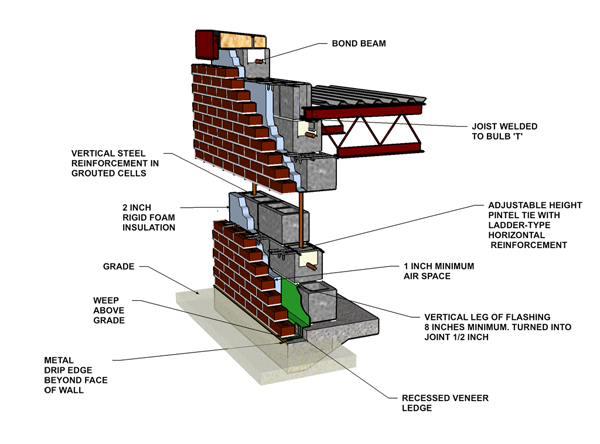

Cavity Wall: Brick Veneer/Reinforced Concrete Block

Resources

- Open 3D Model (get SketchUp)

- Download drawing as .jpg or .dwg

- Print this wall system

- Ask a question

Designed to stand the test of time, this all-masonry wall system pairs a concrete block structure with brick for a beautiful, durable, and maintenance-free façade.

Recommended Building Types

- Schools, commercial and institutional buildings

- Buildings requiring a high fire rating

- Noisy environments

- Areas with frequent rainfall

- Buildings with a long expected life span. The concrete block structural backup will not burn, rot, rust, mold or be eaten by termites.

- Buildings in climates with high humidity. Concrete block is not a food source for mold.

- Choosing the Right Masonry System for your Budget

Benefits

- Tough, beautiful brick exterior over a structural concrete block backup system

- Extremely durable, long lasting wall system

- Minimal long-term maintenance

- Great design flexibility – use different colors, bond patterns, brick sizes, and surface textures to spice up your design

- Concrete block backup acts as the structure, with vertical and horizontal reinforcement grouted into place

- Cavity system inherently weatherproof – great for moist environments

- Excellent insulating value and heat capacity

- Fire proof with gs up to 4 hours

- Great for noisy environments – naturally absorbs sound

- One trade erects both the structural and skin layers of the wall

Special Considerations

- Lower life cycle cost offsets higher initial investment

- This substantial wall system may require larger foundation

Definition and Assumptions

Backup: Lightweight plain gray concrete block (CMU), 8" x 8" x 16" (nom.)

Reinforcement: #6 vertical reinforcement @ 32" on center. 9-gaugejoint reinforcement/wall ties at 16" o.c. (every other course)

Veneer: Modular clay brick 4" x 2-1/3" x 8"(nom.)

Cavity: 3" air space

Insulation: 2" rigid expanded polystyrene in drainage cavity

Flashing: Base flashing and weeps

Veneer ties: Adjustable pintle and eye veneer ties

Mortar: Type N, Portland cement/lime, plain gray

Joints: concave tooled

Regional Variations

- When masonry veneer is used in areas of high seismic risk, veneer ties are required to attach to the wire reinforcement embedded in mortar bed joints in the veneer. Check your local requirements – and save money by using normal veneer ties in areas of low seismic risk.

- Many areas of the western U.S. have good local sources for lightweight aggregate, and the use of lightweight concrete block (CMU) is the norm. In other parts of the country, medium weight and normal weight block are more common.

- Structural masonry walls in areas of high seismic risk are required to have additional horizontal bond beams to resist seismic loads. Check with your structural engineer to determine what is required in your region.

- The use of reinforced bond beams can replace the necessity forjoint reinforcement in concrete masonry walls. Understand that some form of horizontal reinforcement is required in all concrete masonry construction, including veneer applications.

Fire Rating (hours)

Ungrouted Assembly: 4 hrs

Fully grouted Assembly: 4 hrs

- Fire Resistance of Brick Masonry

- Fire Resistance Ratings of Concrete Masonry Assemblies

- Fire Endurance Ratings of Clay Brick Masonry

Sound Transmission Class (dB)

Ungrouted: 55.5

Grouted 32": 57.2

Fully grouted: 61.9

STC=(weight of wall)0.223x21.5Wall Weight (lb/sq. ft.)

Ungrouted: 70 lb/sq. ft

Grouted 32": 81 lb/sq. ft

Fully grouted: 114 lb/sq. ft

Energy Rating

R-value: 11.71 using 2" expanded polystyrene insulation (see note below)

Calculation:

| Outside Air | =0.17 |

| Brick | =0.44 |

| Air Gap | =0.97 |

| 2 inch Polystyrene | =8.00 |

| 8 inch CMU 105 pcf, grouted at 32" o.c. | =1.45 |

| Interior Air | =0.68 |

| Total | =11.71 |

R-value: 13.71 using 2" extruded polystyrene insulation (see note below)

Calculation:

| Outside Air | =0.17 |

| Brick | =0.44 |

| Air Gap | =0.97 |

| 2 inch Polystyrene | =10.00 |

| 8 inch CMU 105 pcf, grouted at 32" o.c. | =1.45 |

| Interior Air | =0.68 |

| Total | =13.71 |

Green/LEED Rating

- Energy efficiency, thermal comfort and energy analysis – up to 10 pts

- Innovation and design – 1 pt

- Recycled content– 2 pts

- Regional material (where applicable) 2 pts

- Concrete Masonry and the LEED Program

- Sustainable Concrete Masonry - Assuring a Healthy Future One Block at a Time

- Sustainablility / Green Building Design

Design Tips

- Place rigid-board insulation in the drainage cavity to maximize interior usable space, and take advantage of the huge thermal mass provided by the masonry backup system.

- Our sample design uses 2” insulation in the cavity, but many designers choose to use 1” insulation. The reason? If you use 1.5” insulation, coupled with a 1” air gap (required by Code), the entire wall can fit on a standard 14” wide foundation if you cantilever the brick a modest 1/8” over the edge of the foundation.

- You can improve the R-value of this wall by substituting 3” foil-faced polyisocyanurate for 2” expanded polystyrene insulation in the cavity. This raises the R-Value of the wall from 11.7 to 21.5. It is important to note that this rigid insulation is continuous. It is penetrated only by thin 9-gauge wire ties to anchor the veneer.

- Brick veneer expands as it ages, whereas concrete block shrinks. Don’t forget to detail expansion jointsin the brick veneer and control joints in the concrete block backup.

- Shelf angles may not be required for veneer support at every floor line. Cut down on the number of shelf angles to save money and simplify your construction. If your veneer is shorter than 30 feet above the top of the foundation wall, you may not need relieving angles at all.

Construction Tips

- Back bevel mortar joints to prevent excess mortar from falling into the drainage cavity. The cavity needs to be open enough to permit water to drain down onto flashing below (ASHRAE 90.1).

- Simplify construction by requesting to use the same mortar type on the veneer as the backup. Type N is usually fine for both, except in high seismic zones where Type S is required.