Figure 1: High-performance polymeric paving sand used in the joints of this installation; these paving sands come in various colors to compliment any architectural design.

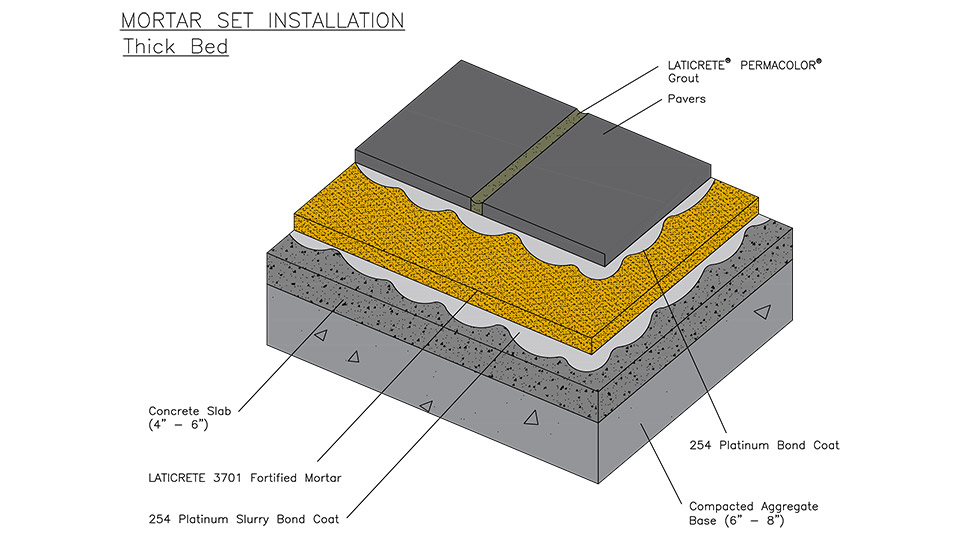

Mortar set installation - thick bed

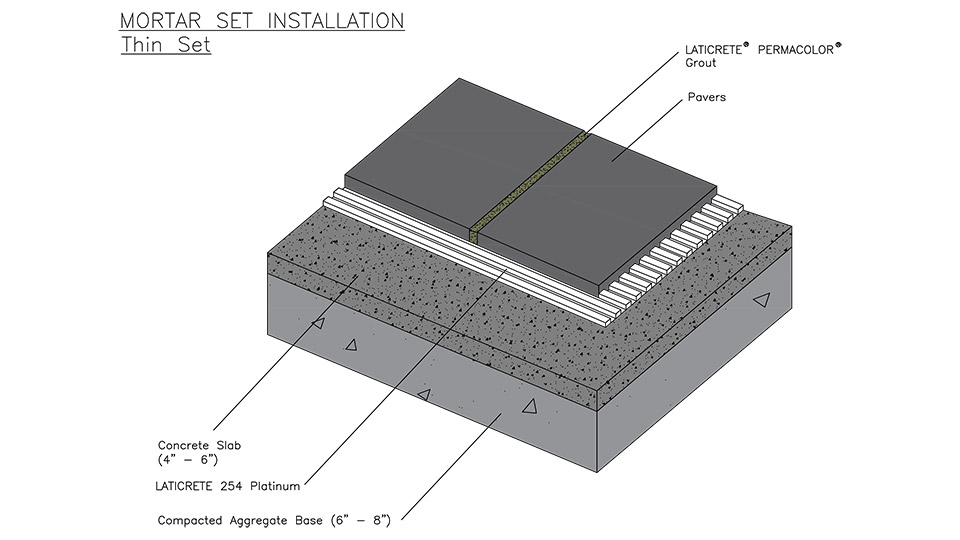

Mortar set installation - thin bed

Figure 2: Exterior driveway/walkway treated with acrylic, scuff resistant coating; finishes typically come in natural or wet-look appearance (wet-look shown here).