Mortar and Grout: Retempering Mortar

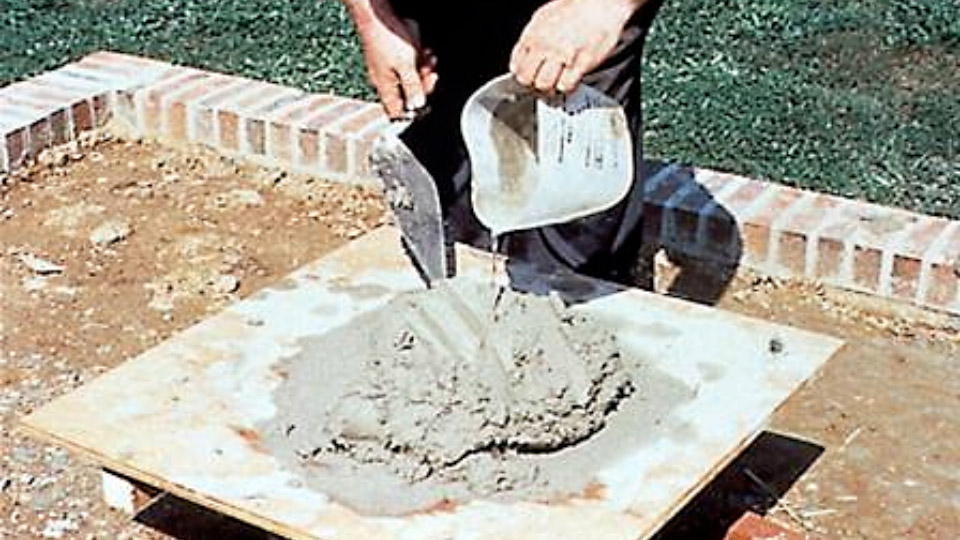

Retempering mortar – adding water and remixing – helps maintain plasticity and workability. Photo courtesy of The Masonry Society.

If you’ve ever worked with concrete, you know it is a big no-no to add water and remix once it starts to stiffen. Some masonry inspectors don’t know that this practice is not only normal with masonry mortar, but is required by Code! Adding water to mortar and remixing is important for maintaining mortar plasticity – we call it retempering (see photo) – and I’ve had inspectors hold up jobs and make us throw away materials because they saw us retempering the mortar.

Mortar starts to stiffen immediately after mixing. Some of the stiffening is due to the mortar drying out as water evaporates, and water added during retempering helps offset this effect. Water evaporates more quickly when it is hot and dry in the summer, and during cool damp weather mortar stays workable much longer. If your mortar has a short board life, get approval to use a higher-lime mortar. Lime has an affinity for water and high-lime mortars have better resistance to dryout and longer board life than high-cement mortars.

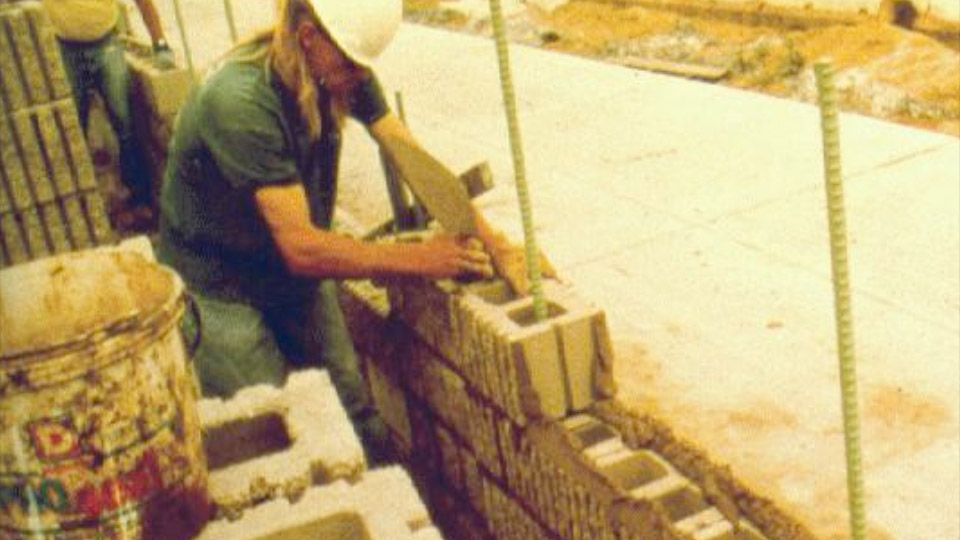

Mortar with proper workability sticks to the trowel and holds at head joints.

Mortar also stiffens as the cement in the mix combines chemically with water in a process known as cement hydration. When cement hydrates, bonds form within the mortar matrix, giving mortar its hardened strength. Mixing up mortar on the mortar board during retempering will break some of these bonds, but we accept sacrificing some of mortar’s compressive strength in the interest of overall quality masonry and good bond.

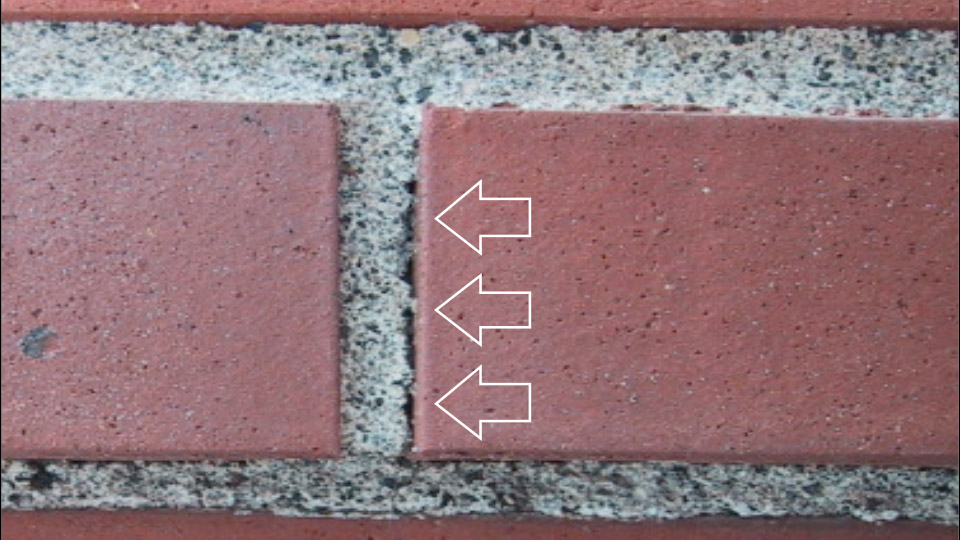

What happens if you don’t retemper mortar at all? When the internal mortar humidity drops to below 80%, cement hydration slows and may halt altogether, reducing mortar strength. Mortar also becomes stiff, losing plasticity over time as water is lost. Stiff mortar is unworkable, unable to adhere to the trowel, and head joint mortar won’t adhere and falls off the end of the block. Even worse, stiff mortar will not fill mortar joints properly and will not bond to brick or block (see photo), leading to leaky walls.

It is difficult to completely fill joints and get good bond with stiff mortar, as seen here. The separation between mortar and brick, known as a bond-line delamination, will let in water during driving rains.

Mortar plasticity is so important for building quality masonry that codes require mortar workability be maintained as it is being used. TMS 602-13/ACI 530.1-13/ASCE 6-13, Specification for Masonry Structures and Commentary, requires in Section 2.6 A., Mortar, that the mason “maintain workability of mortar by remixing and retempering.” But we can’t retemper mortar forever – this same Section tells us to “discard mortar which has begun to stiffen or is not used within 2 ½ hours after initial mixing.”

In hot weather conditions, mortar dryout affects strength and curing, leading to lower strength mortar and poor bond. In hot weather, defined in Specification Section 1.8D as being above 100°F or 90°F with an 8 mph wind, masons are instructed to flush equipment with cold water and to use cool water for retempering. Once mortar is more than 2 hours old no more retempering is permitted and mortar must be discarded.

Be careful with pigmented mortar because retempering can lead to color changes. Mix in smaller batches and follow good hot weather practices so you don’t have to retemper pigmented mortar.