Lintels: Loose Steel or Reinforced Masonry Lintels?

Structural steel lintel with flashing and drip edge.

Lintels used to span masonry openings can be either steel cross sections (plates, angles, I-beams) or of steel-reinforced masonry construction. The design and specification of masonry lintels is typically the responsibility of the project structural engineer. Which lintel type is better depends on the specific situation. Below are bulleted pros and cons to assist in lintel type selection.

Loose Steel Lintels – Pros and Cons

+ Loose steel lintels work well for masonry veneers.

+ The masonry veneer forms the fire protection for the steel.

+ Loose lintels don ’t require temporary shoring.

- The bearing of steel lintels may interfere with vertical reinforcing commonly at jambs in load-bearing masonry.

- Corrosion protection, such as zinc galvanizing or paint is necessary for loose lintels in exterior walls.

- Fire protection may be needed for exposed lintels in load-bearing masonry or larger (over 8 ft.) openings in veneers.

- Steel lintels get heavy and awkward for larger openings and need to meet code deflection criteria of length/600.

- Differential movement between steel and masonry will have to be considered and accommodated.

Loose Steel Lintels – Pros and Cons

+ Loose steel lintels work well for masonry veneers.

+ The masonry veneer forms the fire protection for the steel.

+ Loose lintels don ’t require temporary shoring.

- The bearing of steel lintels may interfere with vertical reinforcing commonly at jambs in load-bearing masonry.

- Corrosion protection, such as zinc galvanizing or paint is necessary for loose lintels in exterior walls.

- Fire protection may be needed for exposed lintels in load-bearing masonry or larger (over 8 ft.) openings in veneers.

- Steel lintels get heavy and awkward for larger openings and need to meet code deflection criteria of length/600.

- Differential movement between steel and masonry will have to be considered and accommodated.

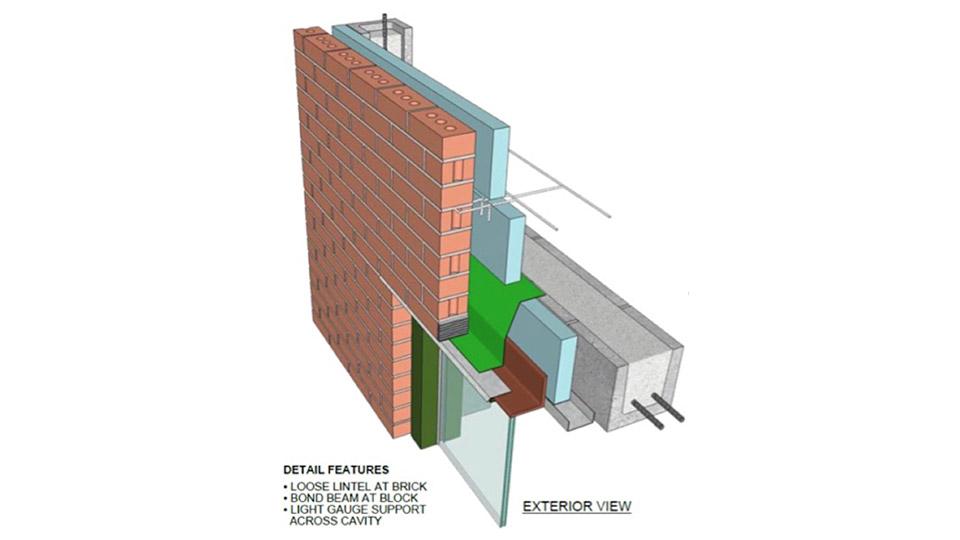

Loose lintel for support of the brick veneer and reinforced CMU lintel in the load-bearing backup (image courtesy of the International Masonry Institute’s Masonry Detailing Series).

Keep in mind that heads of masonry wall openings require flashings with end dams and weep holes. The Brick Industry Association (BIA) has several Technical Notes to provide further guidance. Technical Note 31B provides guidance on the design of steel lintels and Technical Note 7 provides good information on proper flashing details for lintels.

While not part of the discussion above, unreinforced masonry arches are possible in situations where there is adequate masonry mass to resist the thrust generated by the arch. With insufficient mass due to thin end piers or limited wall area, arches can be supported on curved steel lintels. Please refer to BIA Technical Notes 31, 31A and 31C for further information on masonry arches.

Reinforced masonry lintel design in CMU construction is discussed in the National Concrete Masonry Association ’s (NCMA) Tek 17-1D. Flashing details for CMU cavity and single-wythe walls are given in Tek 19-05A.