Foundation: Dealing with Foundation Issues Supporting Masonry

Words: Michael Schuller

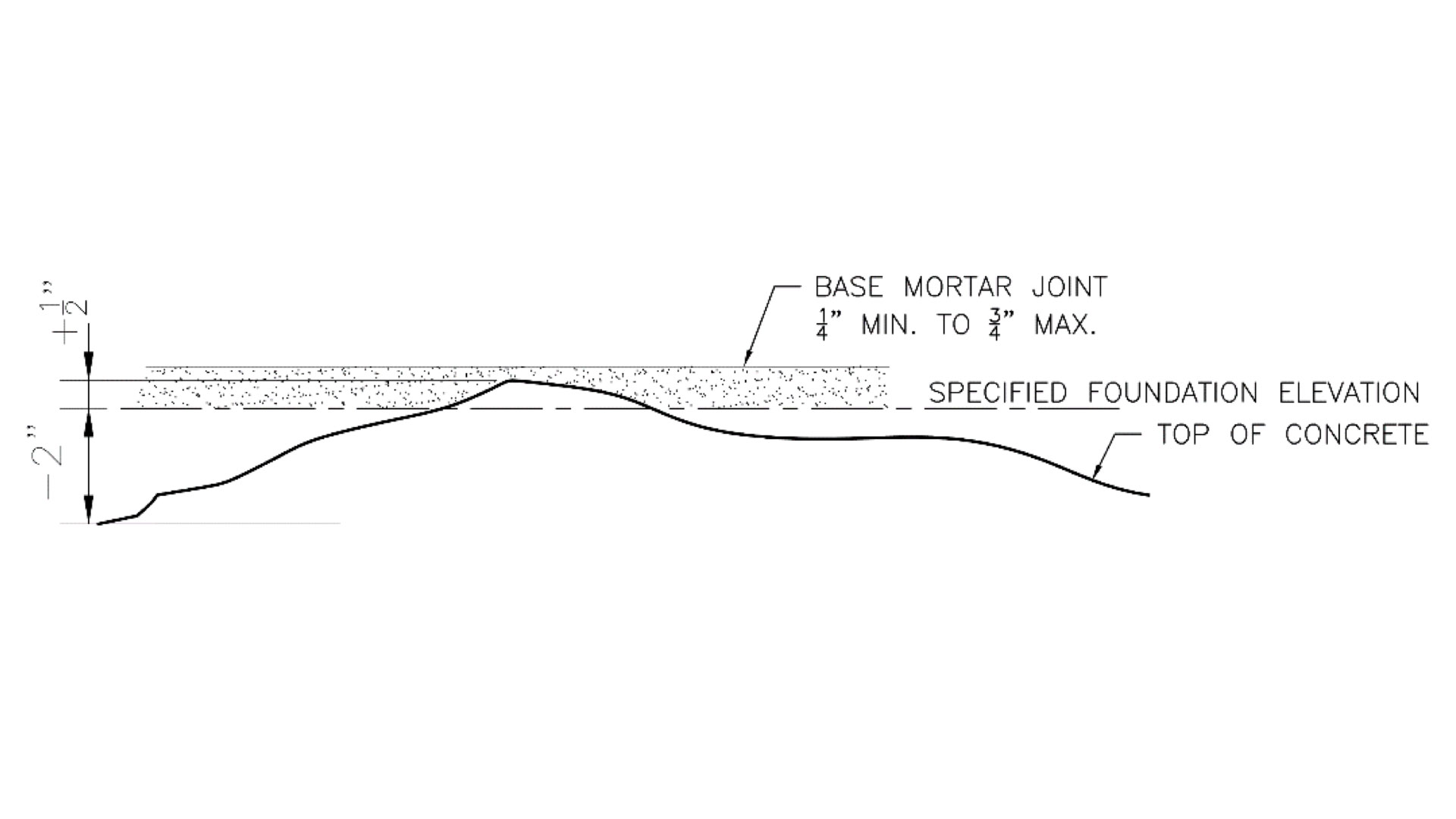

Concrete tolerances exceed base mortar bed joint limits.

Loadbearing masonry should be fully supported by footings or foundation walls, and masonry veneer normally rests on a concrete brick ledge or shelf angle at the foundation level. Everything works great if the concrete contractor installs quality work, but what do you do when the foundation walls are misplaced?

Masonry Construction Tolerances

Masonry construction tolerances are the tightest in the industry – and this leads to conflicts if the concrete foundation is not built to “masonry precision.” Talk about this at the pre-construction meeting, and make sure the concrete subcontractor is aware of Code tolerances for masonry construction.

Make sure to check the top of the foundation for level and elevation – all the way around the building – before laying the first course. For load-bearing masonry, the TMS 602 Specifications for Masonry Structures require that the bed joint for the first course be at least ¼ inch thick but not more than ¾ inch when the masonry is ungrouted or partially grouted. This joint thickness is increased to 1¼ inch when the first course if fully grouted and supported by a concrete foundation.

TMS 602 Specifications Section 3.3 F lists tolerances for masonry construction, but these requirements do not apply to masonry veneer (according to IBC Section 1405.5.1, and TMS 402 Section 12.1.1.3). Be sure to check your project specification, because it may include construction tolerances for veneer that mirror those contained in the building code. It is common to have tolerances listed in project specifications stating that masonry must be built to be true to a line to within ± ¼ inch in 10 feet, ± 3/8 in 20 feet and ± ½ inch maximum.

Concrete Foundation Tolerances

According to the American Concrete Institute, ACI 117 Tolerances for Concrete Construction, the front edge of a foundation wall supporting masonry must be built to within ± ½ inch of the specified location, the same as the maximum masonry construction tolerance.

The 2011 Residential Construction Performance Guidelines, published by the National Association of Home Builders (NAHB), provides construction tolerances as a listing of observations. These tolerances are more liberal than ACI tolerances, permitting concrete foundation walls to be ±1” out of square in any 20-foot length, and ±1” out of plumb or bowed in any 8-foot height. These tolerances exceed those required for masonry.

ACI 117 permits the top surface of concrete foundations to be as much as ½” higher or 2” lower than the specified elevation (see Figure). That means your base bed joint could be as much as 2 1/4” thick to start the base course at the correct elevation. Code does not permit a 2” thick mortar, but there are some options for correcting the condition.

- Grout the base course solid, in which case your base mortar joint can be up to 1 ¼” thick and still meet Code. This only works for hollow-unit masonry.

- Build up low spots with non-shrink grout.

- Trim masonry units to fit.

- Chip or sawcut concrete to bring the foundation down to the correct elevation. This may not be permitted, structurally, and may also involve resetting all of the foundation dowels.

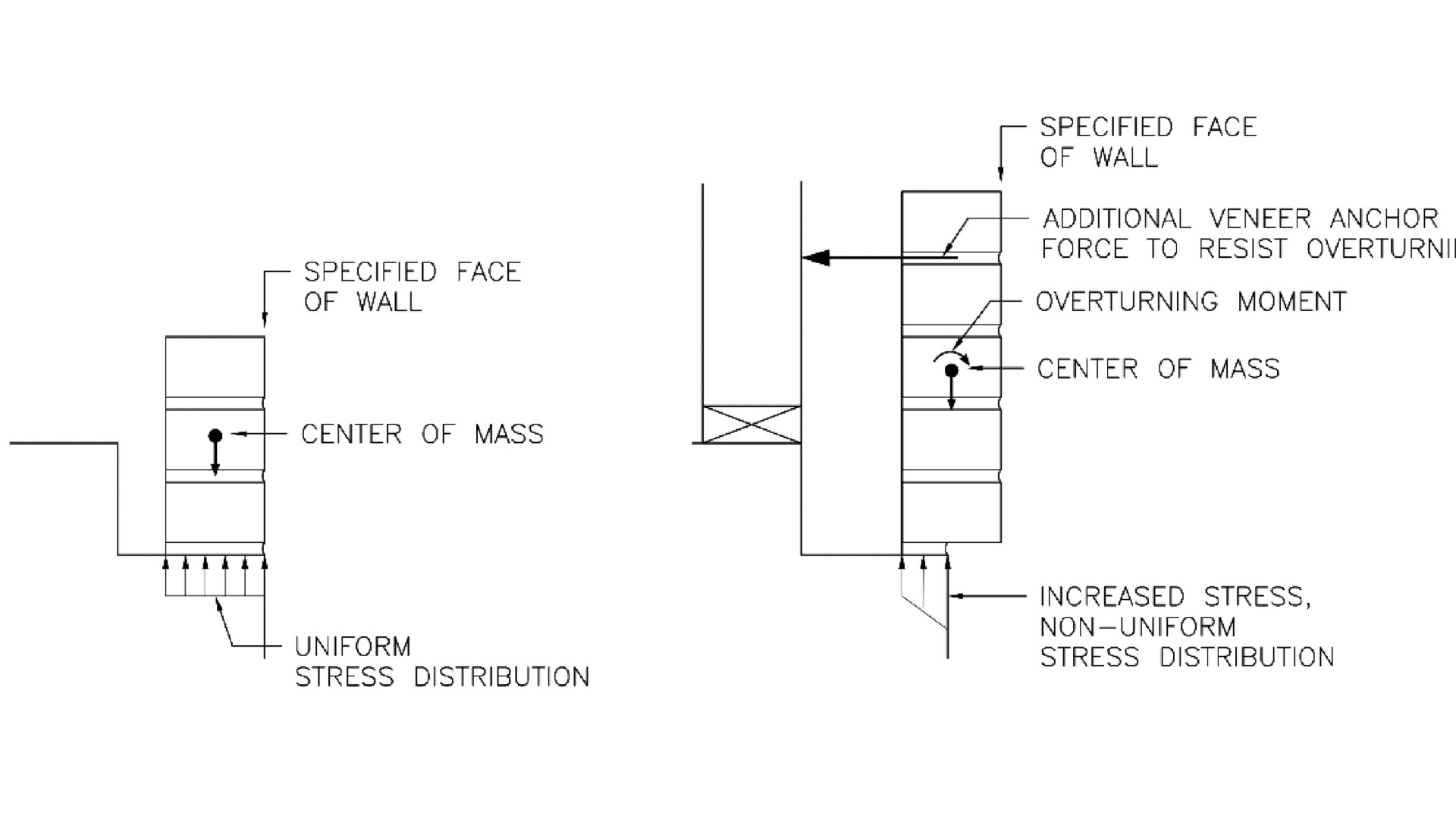

High stress develops where veneer overhangs the brick ledge.

Solutions

When walls hang over the edge of foundation supports, stress concentrations and overturning moments develop. Check with your engineer – it is rarely acceptable for loadbearing masonry to have anything less than full support at its base, but in some cases it may work to install extra veneer anchors to resist overturning forces. (Figure)

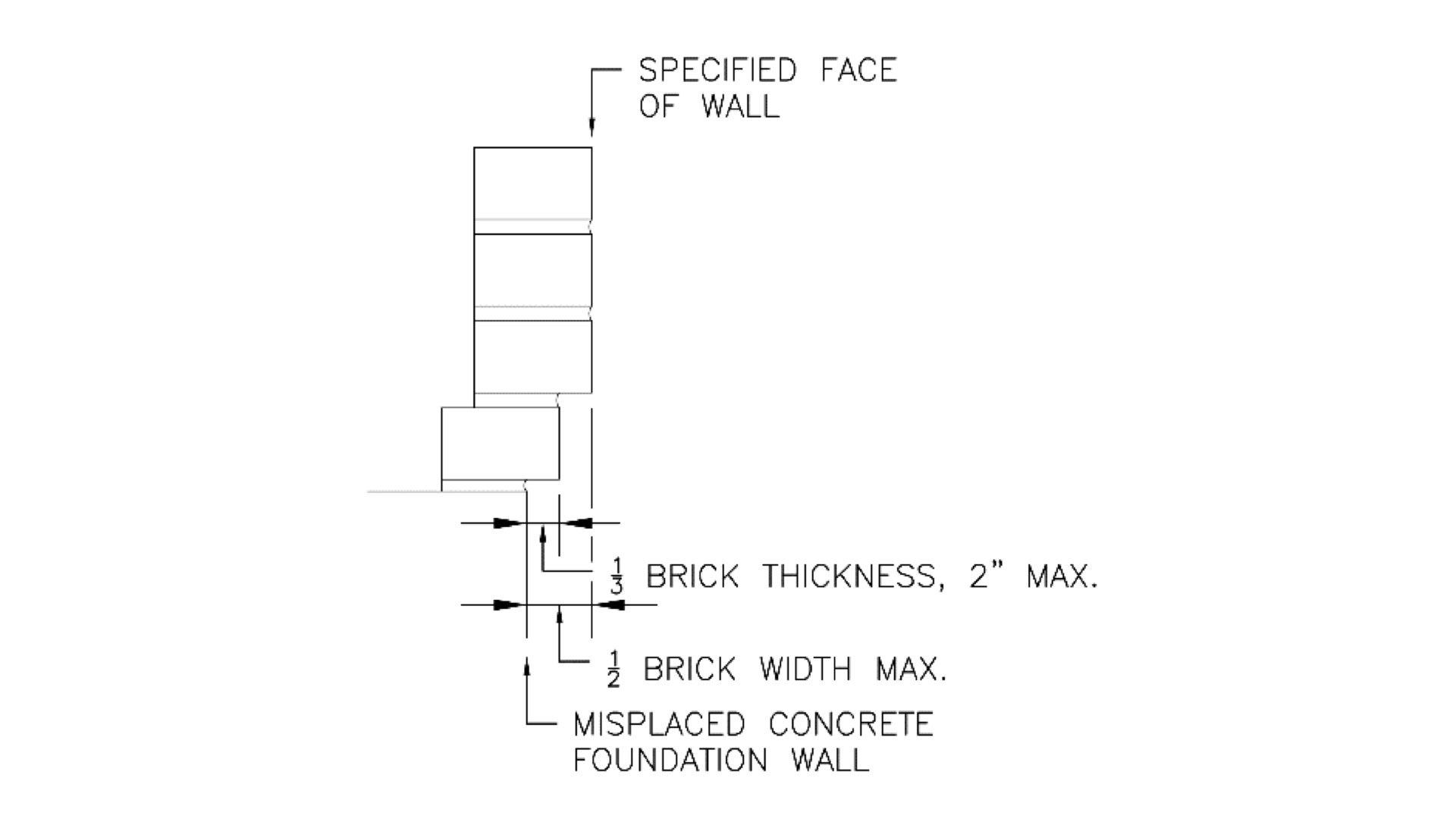

Brick corbel

For a masonry veneer, the masonry can be laid with full support on the foundation and corbel out over the first few courses to meet the specified wall location. Using solid masonry or grouted hollow units at the base course, TMS 402 Section 5.5 permits each masonry course to project beyond the face of the wall by up to ½ the nominal unit height, or 1/3 the unit width. For modular brick that means the veneer can corbel out by 1 ½” each course. Use multiple corbeled courses at the base of the wall to corbel out a maximum of ½ the wythe thickness, or 2” for modular brick. (Figure)

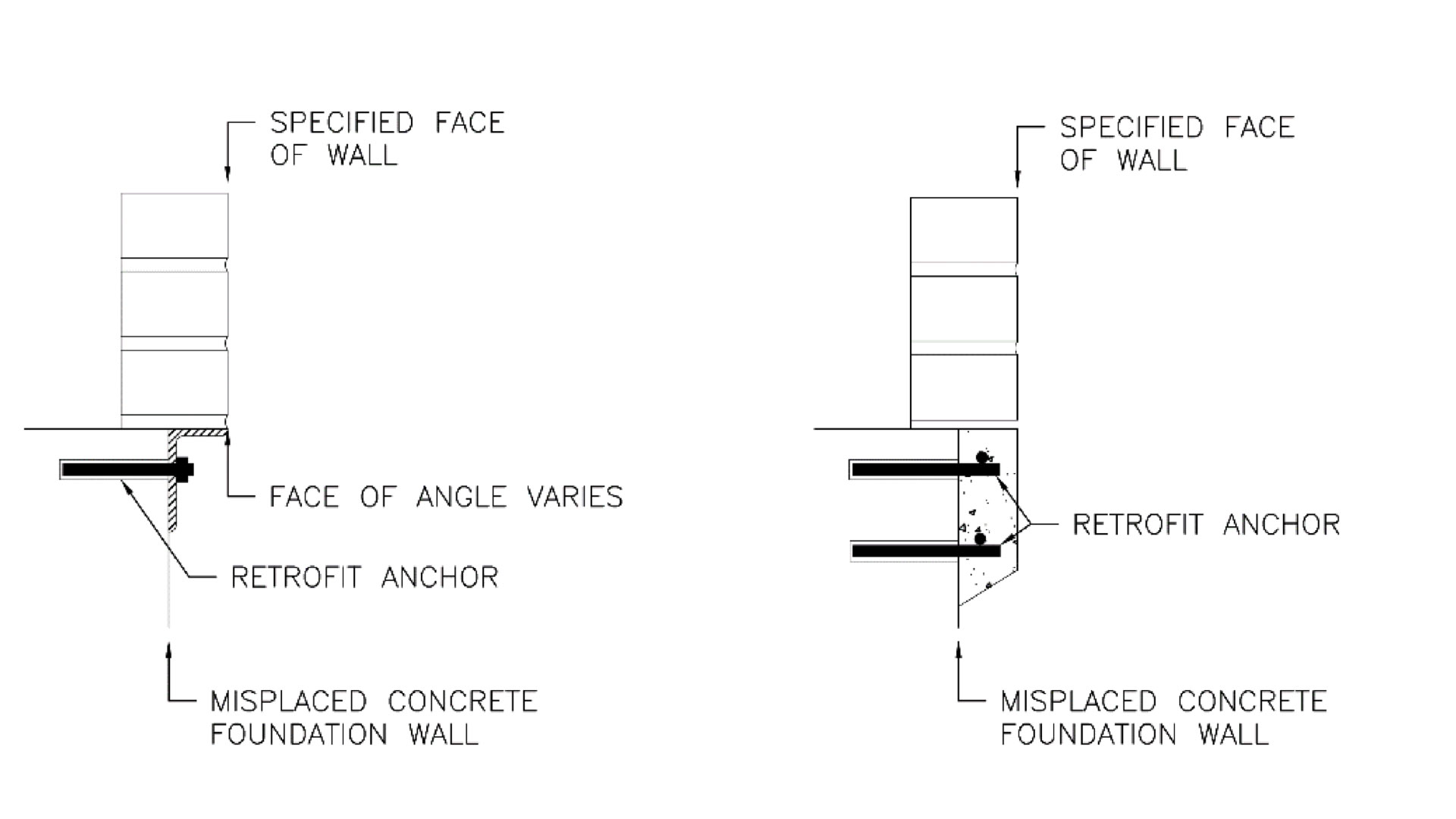

Shelf angle and concrete corbel support.

It is possible for veneer to project out over its support by more than these limits if the condition is engineered. Masonry projecting over ½ of the veneer thickness develops high stress at the face of the foundation wall when the veneer center of mass is located outboard of the foundation wall face. This condition will also develop an overturning moment and will often require additional veneer anchors to resist this force (Figure). Other options are to retrofit the foundation support by adding a steel shelf angle or concrete corbel (Figure). Both of these solutions will have to be engineered to make sure the foundation and masonry can handle the added stress.