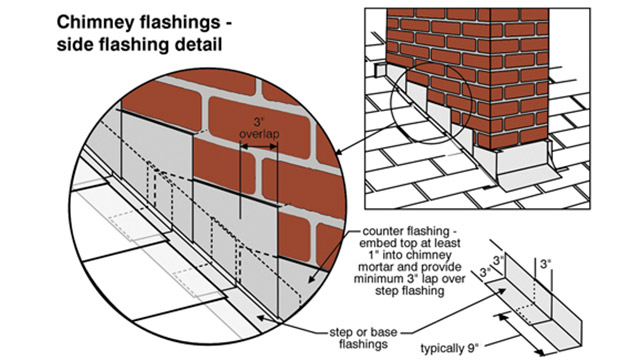

Chimney flashings - side flashing detail

The counter flashing is missing on the side of this chimney.

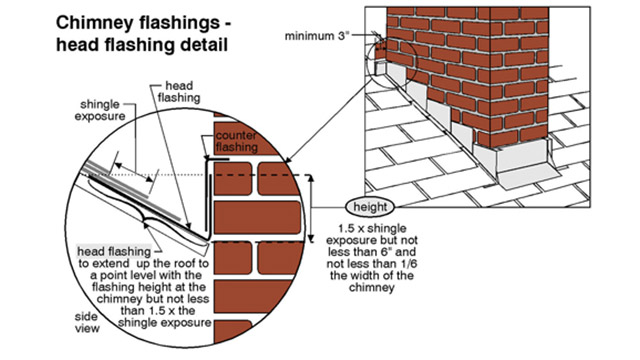

Chimeny flashings - head flashing detail

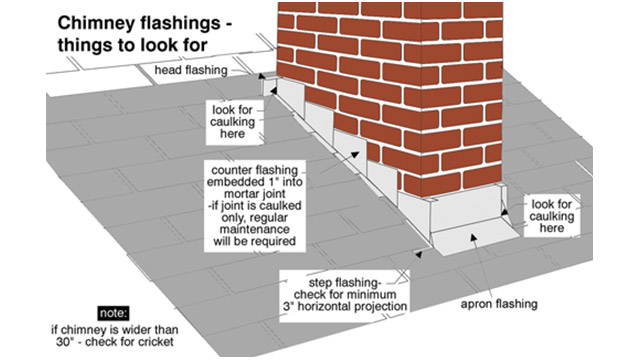

Cricket or saddle has been removed from this masonry chimney wider than 30 inches.

The head flashing here is not caulked or embedded into the mortar.

Chimeny flashings - things to look for

Flashings that are not embedded into the concrete require continual maintenance.